Noise and vibration,

our business your comfort on board

With more than 50 years of experience, Intersona BV is the noise and vibration consultancy firm for ships worldwide. Drawing on decades of knowledge and extensive experience, our consultants provide shipyards and shipowners with practical solutions to minimize noise and vibration issues. As independent experts, we base our recommendations for noise and vibration reducing measures on physical principles and technical properties of materials. Intersona is certified by Bureau Veritas to carry out noise and vibration measurements related to the COMF additional class notation (COMF NOISE and COMF VIB).

Design and engineering phase

At Intersona, we proudly support a broad spectrum of maritime projects, working on all types of vessels from the initial design phase through to active

operation. During the design phase, our experts provide calculations, advice, and drawings related to noise and vibration.

Evaluate noise and vibration sources

Our experts can assess all

relevant noise and vibration

sources, including machinery

mounting. We provide

recommendations to minimise

noise and vibration at the source,

resulting in improved comfort

throughout the entire vessel.

Noise level prediction

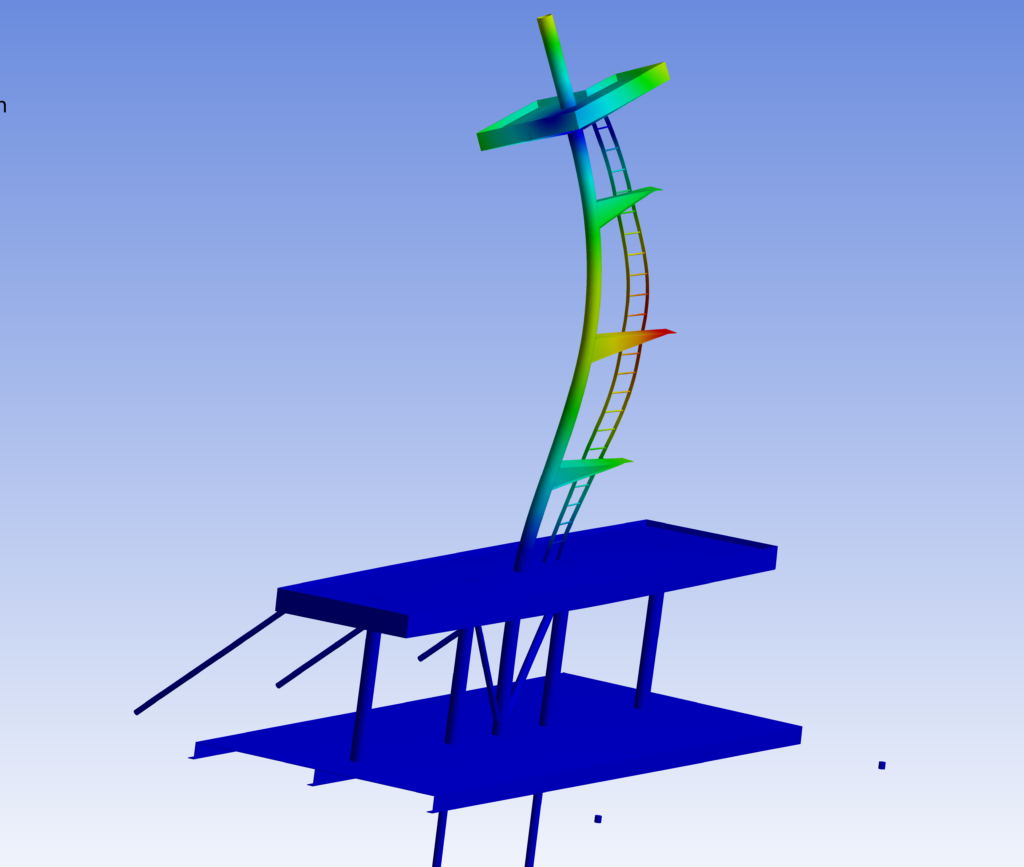

Natural frequency calculations

Our experts can calculate

natural frequencies using

analytical models and/or FEM

(modal analysis). Based on the

predicted natural frequency and

excitation frequencies of vibration

sources, effective measures can be

recommended to prevent

resonance.

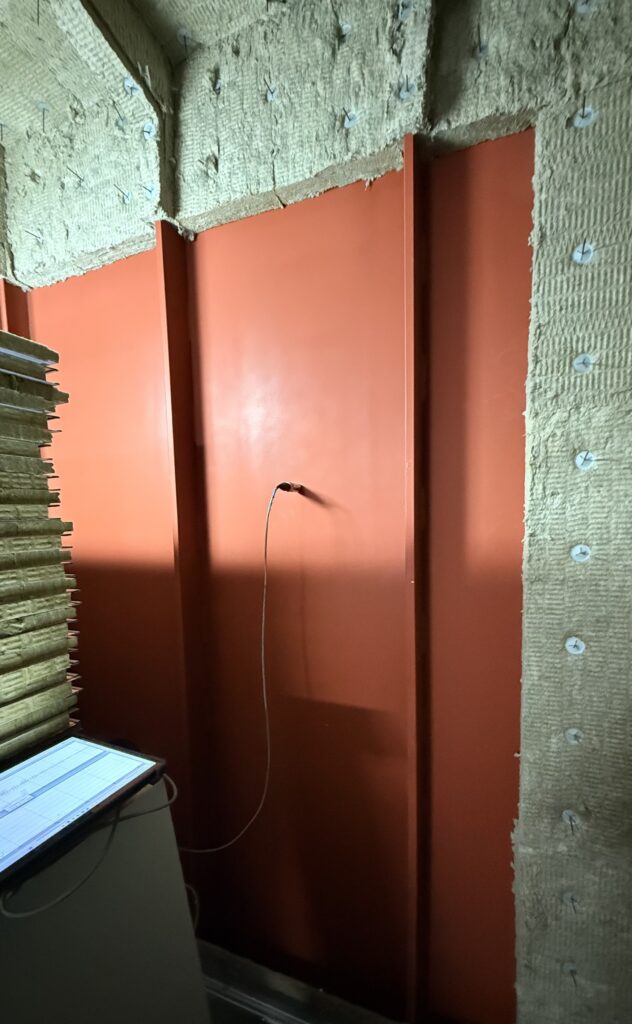

Design and assess insulation & floor plans

Construction phase

During the construction phase, Intersona’s experts review designs and calculations of suppliers, conduct visual inspections, and perform natural

frequency measurements.

Assessment of designs and calculations of suppliers

Visual inspections

Natural frequency measurements

Commissioning & operation phase

During the commissioning phase, Intersona conducts measurements during sea trials to verify whether the ship meets the previously agreed-upon requirements. These measurements, including analysis and reporting, are carried out following the IMO and ISO requirements. In addition, if damage occurs that may be related to vibrations, Intersona’s experts can carry out measurements to help troubleshoot the issue. These troubleshooting measurements aim to identify the root cause of vibration-related damage by providing insight into the dynamic properties of the relevant systems.

Noise measurements

Noise measurements can be

performed by Intersona using a calibrated Class 1 sound level meter, including noise spectra analysis with one-third octave bands and fast Fourier transform.

Vibration measurements

Our experts can perform vibration measurements using calibrated sensors and an analyzer, including recording

waveform and vibration spectra analysis (one-third octave bands and fast Fourier transform). We assess vibration levels related to (dis)comfort, and potential damage risks, aiming for

long-term machinery operation.

Shaft power measurements

Intersona experts can perform power measurements on shafts using strain gauges and shaft speed measurements. For propeller shafts, propeller curves can be determined. These measurement results can be used to assess ship speed and for EEDI calculations.

Other measurements

- Torsional vibration measurements (strain gauge, laser)

- Bollard pull measurements (load cell)

- Whirling measurements (proximity transducer, laser)

- Dynamic displacement measurements (laser)

- Dynamic pressure measurements

- Multi-channel measurements